Pressure booster systems with fully automatic speed control

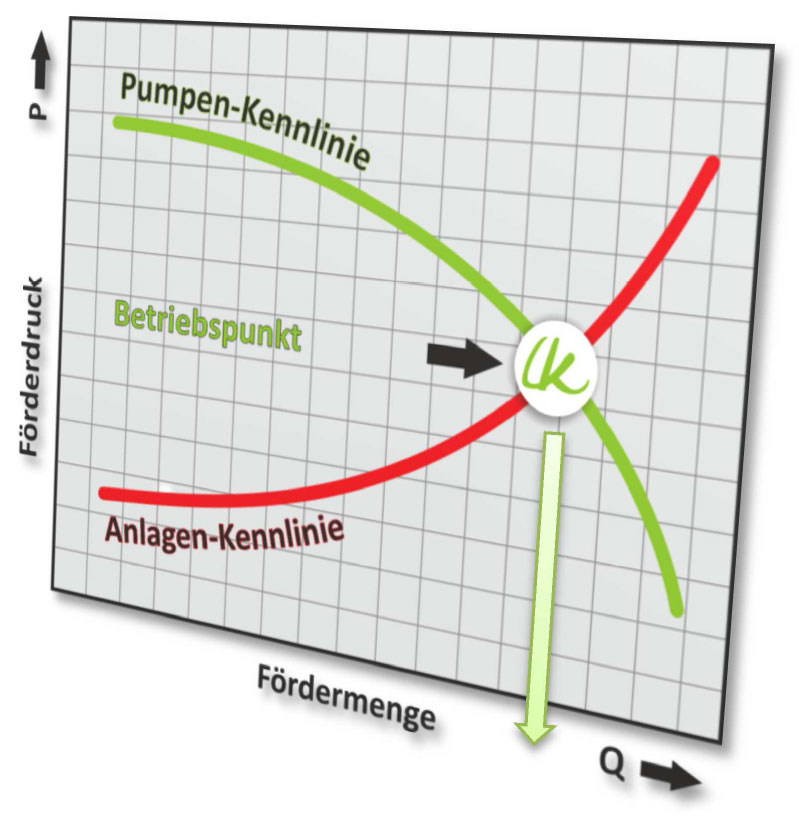

We design and build pump stations for industrial as well as municipal applications. By systematic advice, always with the focus on optimal technical and especially on the economic function, you receive from us pump units and pump stations for the pumping of waste water, drinking water and industrial water. We always design a solution based on your specifications, in which price and performance are coordinated. We fulfill your demand for sophisticated and reliable solutions with our decades of experience and competence.

Applications

- Industrial processes

- Municipal water supply

- Fire-fighting equipment

- High buildings

- Widely branched pipe networks

Your advantages

- Design according to your specifications

- Individual customer care

- Hygienically safe

- Reduction of operating costs with state-of-the-art control technology

- Reduced wear

- Reliable and durable

- Highest quality

Efficient – Reliable – Flexible

The fully automatic speed control optimizes the drive frequency of the motor to the constantly changing needs.The delivery rate and delivery pressure are sensitively adjusted to the varying requirements so that you will no longer feel any pressure fluctuations in the system. Also, a swingin intake pressure is balanced to ensure constant conditions for your efficient processes.The systems are designed with redundancy for your operational safety and are also capable of running on emergency. You can thus realize an energy saving of up to 70 percent.

Even existing systems can be easily retrofitted. Talk to us, we will be glad to help you to use your resources optimally and economically.

Saving energy with centrifugal pumps

Intelligent speed regulation for water supply and pressure elevation

Reduce your energy costs

The enormous increase in electricity prices in recent years has had a particularly serious impact on suppliers of water.

Old pump controls in water supply and pressure elevation systems operate on partial load which, on a systemic basis, is very uneconomical and no longer modern – however with a little work, these controls could be modernised.

Retrofitting with a speed control system reduces energy consumption considerably and it also protects the environment as a result of low CO2 emissions.

The assembly of the speed controller is simple and cost-effective and can be performed on any standard motor. It does not require any intervention with the hydraulic components of the existing system.

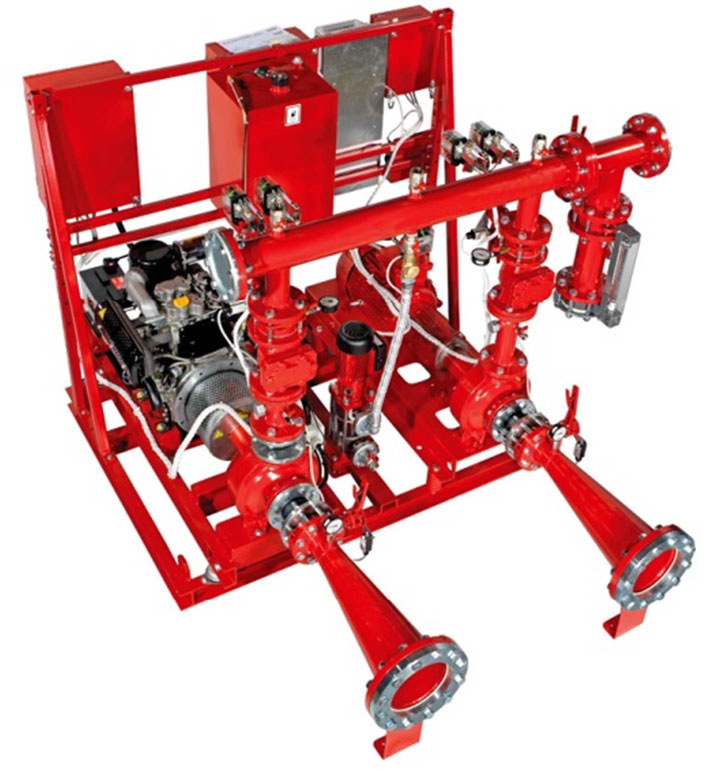

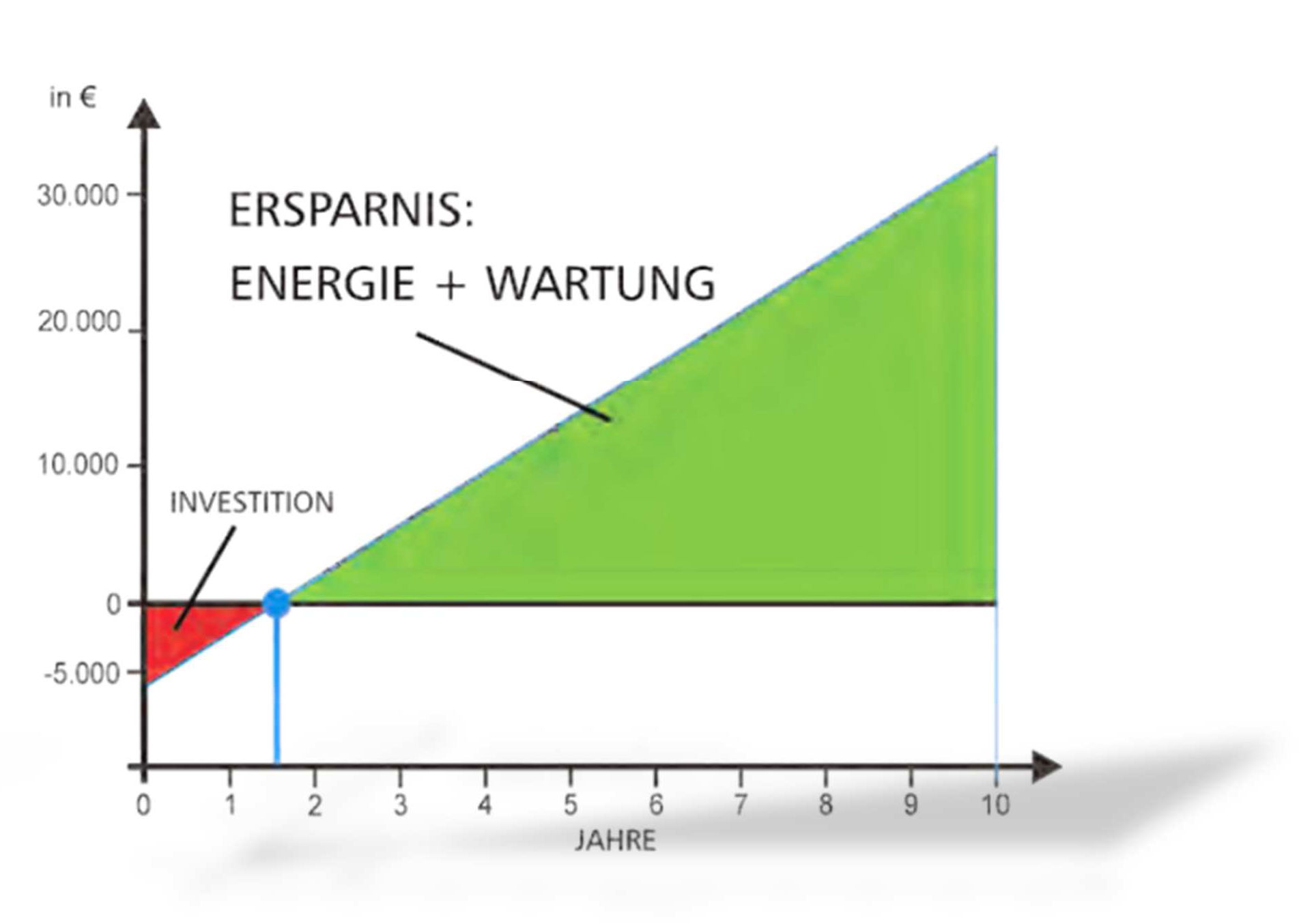

The life cycle cost diagram shows the enormous share devoted to energy. This can often be saved with a 5 figure investment. Depending on the type of operation and the size of the system, the retrofit will usually pay for itself between one and three years.

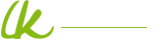

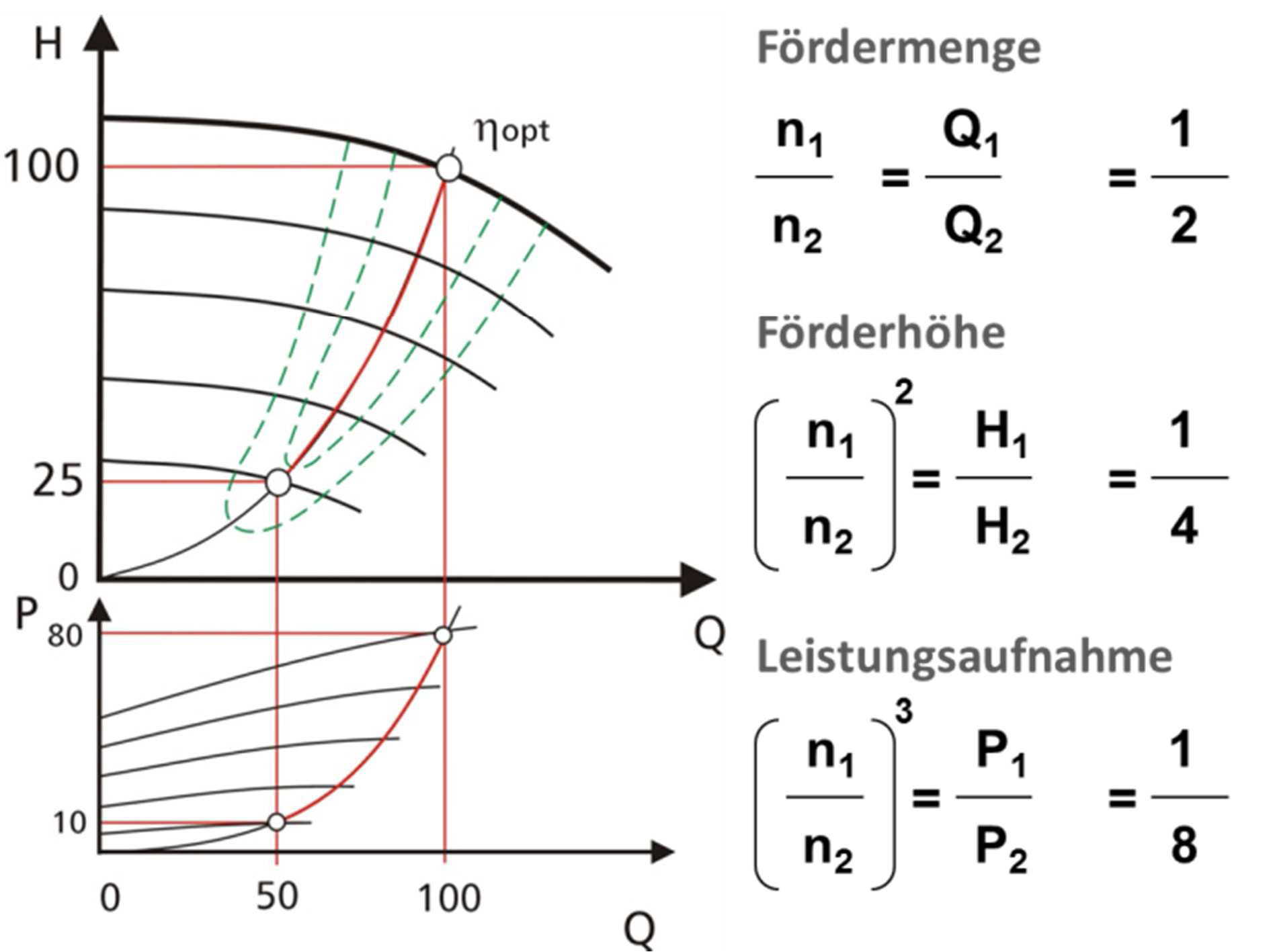

Constant line pressure

The speed control system regulates the speed of the pumps in a way that is infinitely variable, thus adapting the flow rate precisely to the current demand. The reduction in speed causes a 3rd power reduction in the power consumption. The physical formulas are shown in the table on the left. Pressure losses in the pipe network are also automatically compensated for. This results in an additional energy saving in the case of small and medium-sized flow rates.

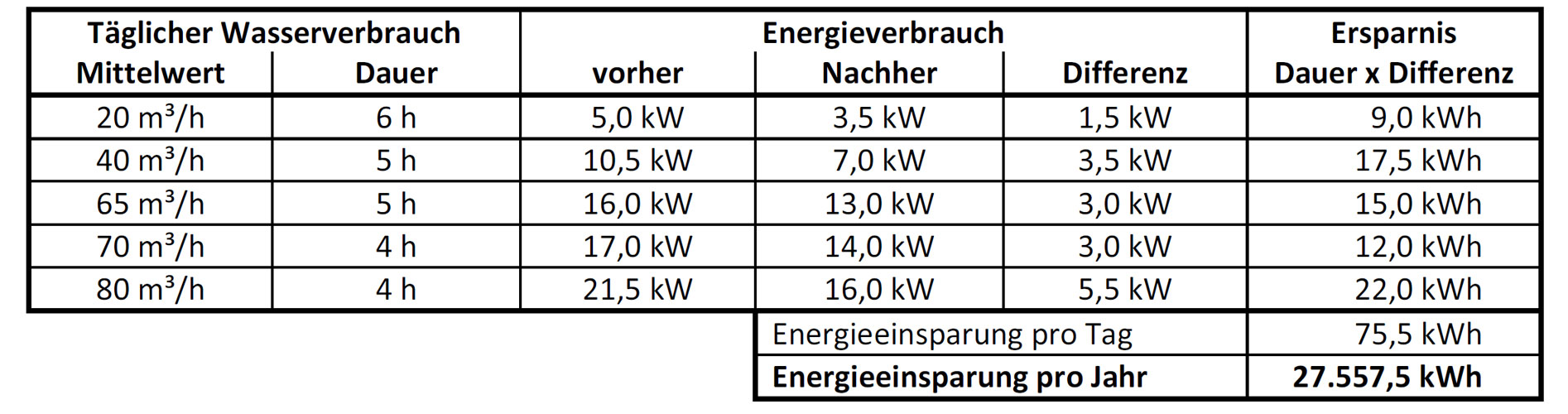

Example calculation on the basis of a water supply system consuming 1250 m³ of water per day:

The reduction of the pump speed and the automatic shutdown of the pumps in the case of 0-feed leads to lower operating costs. This is because the wear and tear is significantly reduced.